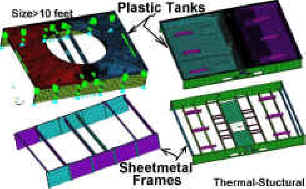

Plastic Tray on Steel Frame

Performed “forensic” FEA to determine why a newly designed product line was failing in certain Rooftop climates.

Client was assuming their own factory-made plastic-welds were substandard and “failing”, but simulation proved it was an intrinsic design problem because they did not accommodate Plastic/Metal differential thermal expansion/contraction over a 14 foot plastic/metal span! Our ANSYS Simulation proved that even a “perfect” Plastic Poly weld would have failed under the circumstances….

- Thermal/Structural FEA (thermal expansion stress)

- FEA reproduced the failures on these 14′ assemblies

- Ascertained that manufacturing variations were not solely responsible for failures. Client to redesign mounts & connections to allow some motion.