FEA Meshing

Since we are independent FEA consultants we take pride in our flexibility. Our FEA consultants can work in tandem with clients or they can manage a project comprehensively. We complete the simulation prep or the entire simulation while working with the client to produce a mesh that fits their needs best. We will also work nights and weekends so that our clients will not need to.

Clients who outsource FEA meshing enjoy shorter analysis cycles, conserve internal resources, and benefits from the experience of an FEA expert.

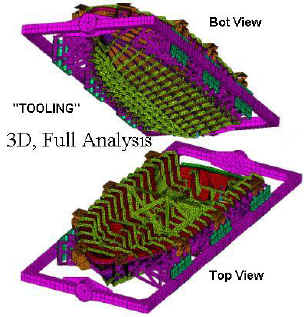

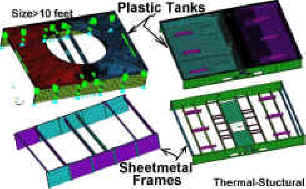

In2Solutions runs effective FEA for any type of material. Whether a project involves common plastics and metals, or involved more complex material, we can perform linear and non-linear analyses as needed. Through mesh refinement we uncover stresses and displacements with great accuracy. Discovering limitations allows for correction before the time and resources are expended on creating a prototype. A proper mesh reduces the time to solve these issues and assures reliable simulation outcomes.

For existing FEA users, In2Solutions converts existing CAD geometry to high-quality FEA mesh. Our FEA meshing experts use classic ANSYS or ANSYS Workbench. We provide TET, Shell, Beam/Pipe, and Brick (or predominantly Brick) ready-to-use FEA models. Our meshing services involve necessary model modifications, repairs, and mid-planing.

Our FEA consultants operate on either a fixed-fee basis or by a competitive hourly rate. Discuss your FEA meshing needs with In2Solutions to develop a plan you can start right away.